Crusher and Standard Process

Source file: 4. crusher-and-standard-process.htm

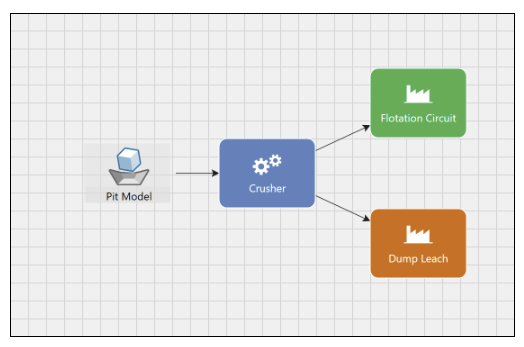

Crushers receive ore from pits and pass it on to standard processes. Standard processes represent processing streams that produce a saleable product and revenue for the mine. One crusher can feed multiple processes, and a process can be fed by multiple crushers. Crushers and processes have separate, individual capacities, which allows you to model complex scenarios. In these scenarios the crusher can limit the total capacity of the plant, and Strategy will determine how much ore will end up in each process to maximise net present value (NPV).

Apart from grouped processes (see Process groups for more information), each individual process will have an optimal cut-off grade found for each period in the schedule.

In the ![]() Calendar subtab, you can set the following:

Calendar subtab, you can set the following:

-

- The capacities for crushers and processes

-

- The sale prices for saleable products produced by processes

The ![]() Configuration subtab allows you to set the following:

Configuration subtab allows you to set the following:

-

- Processing costs

-

- Recovery factors

For more information, see Calendar and Configuration.

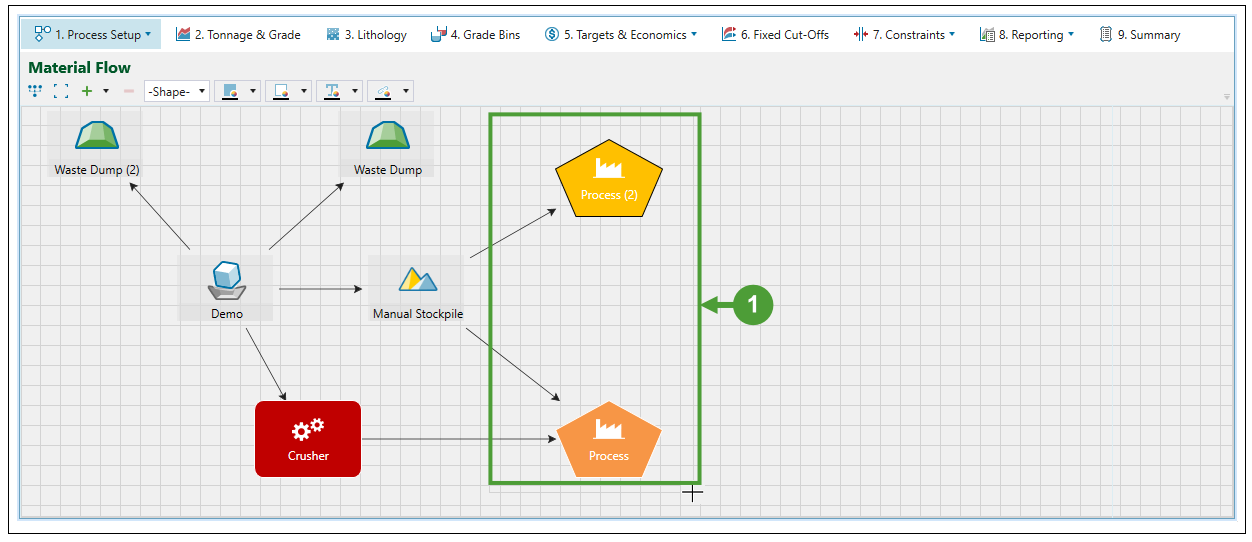

Process groups

Evolution allows you to group the processes in your flowchart, so that the material that is being sent to the created group can be optimally processed at the node that has higher financial return. Therefore, process grouping helps to streamline the efficiency of material handling and contributes to achieving higher financial benefit.

By default, Strategy generates an optimal cut-off grade for each process in the setup. However, sometimes it is desirable to model multiple processes that share the same cut-off. This can be achieved with process grouping. When material is sent to the group, Strategy will send it to the process that still has processing capacity that will provide the greatest profit for that material.

To create a process group:

-

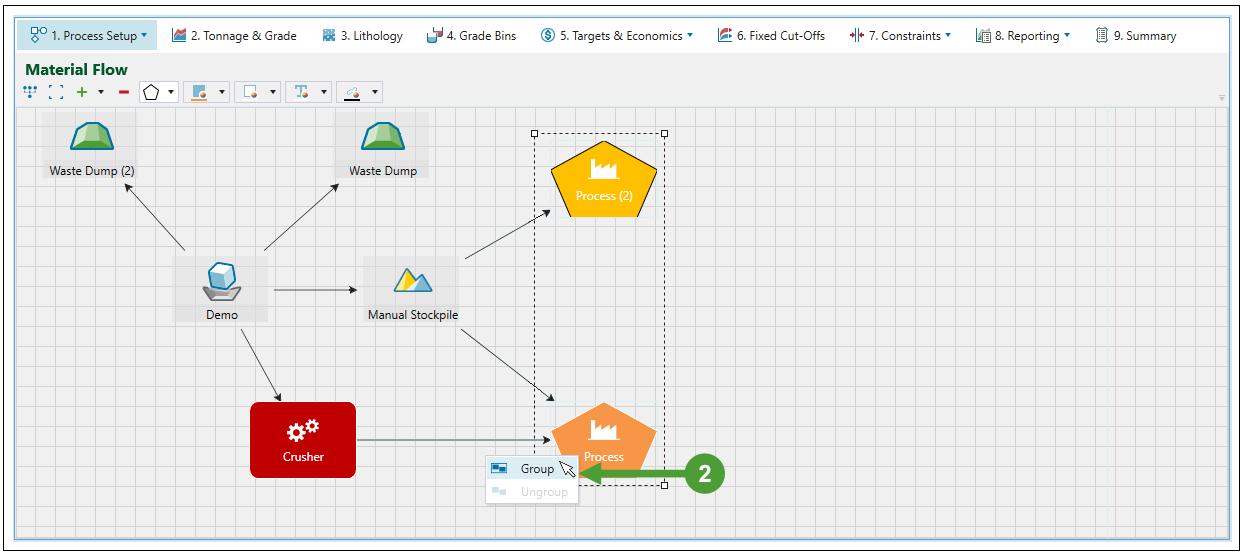

Select the required processes in your flowchart by dragging a rectangle over them.

-

Right-click on one of them and select Group.

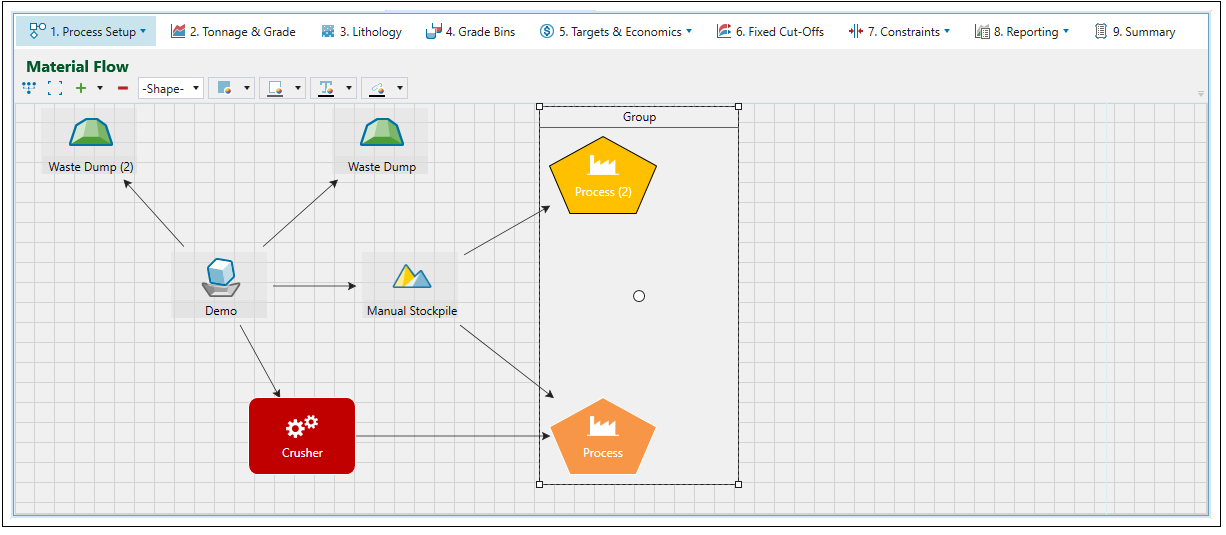

The process group will be created in your flowchart.

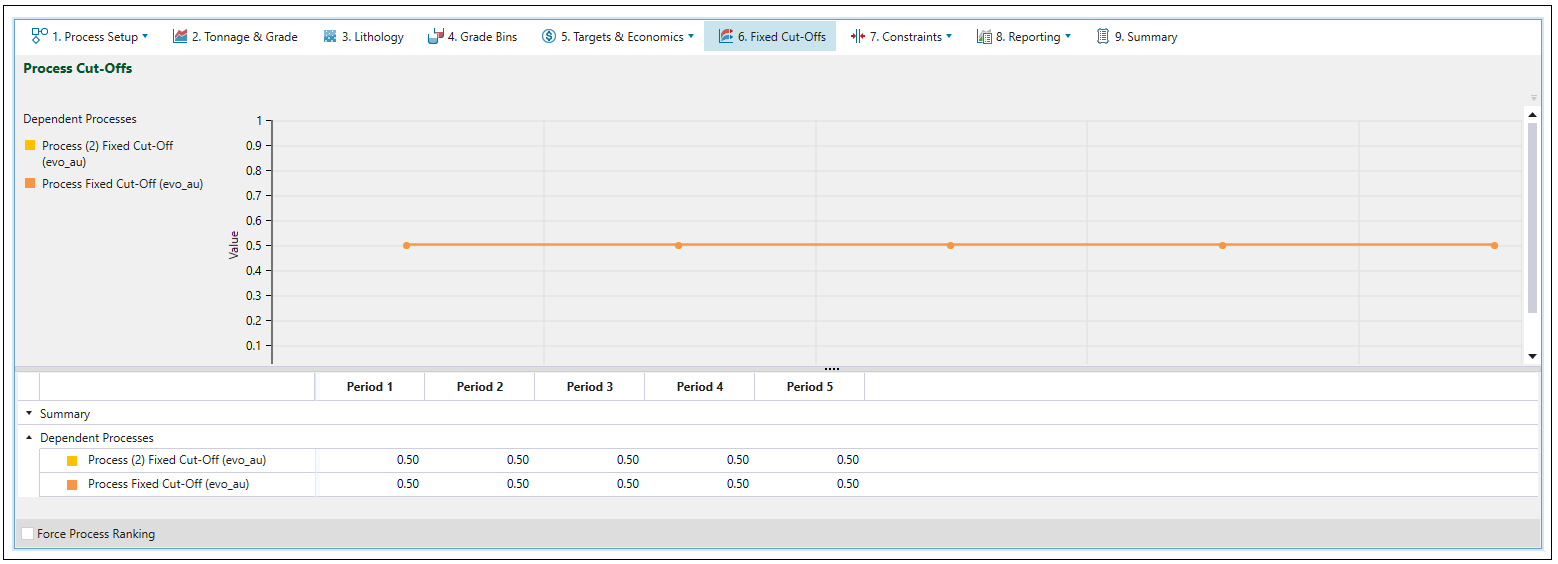

Once a process group is created, the engine will generate a single cut-off for all processes in the group. See Fixed Cut-Offs for more information.

Tip: To set a fixed cut-off, assign the same cut-off to the processes within the same group.

Note: Each process will still be reported separately in the schedule and pivots. For more information on schedule and pivot data, see Schedule Report and Pivot Reporting.

Strategy calculations

| Crusher feed and grade |

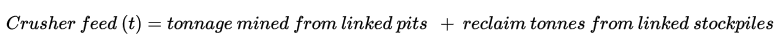

Crusher feed tonnage is calculated according to the following formula:

where Crusher feed grade is the weight average grade of ore mined from the linked pits and reclaims from the linked stockpiles. You can specify the tonnages and grades in the |

| Metal/Product |

The amount of metal or product that is produced by a given process is calculated according to the following formula:

You can set the ore tonnes and grade in the |

| Revenue |

The revenue that a given process generates is calculated according to the following formula:

You can set the element price and selling cost in the |

indicates the calculated tonnes.

indicates the calculated tonnes.